For all types of electronic assembly, please contact us for a free quote with no obligations.

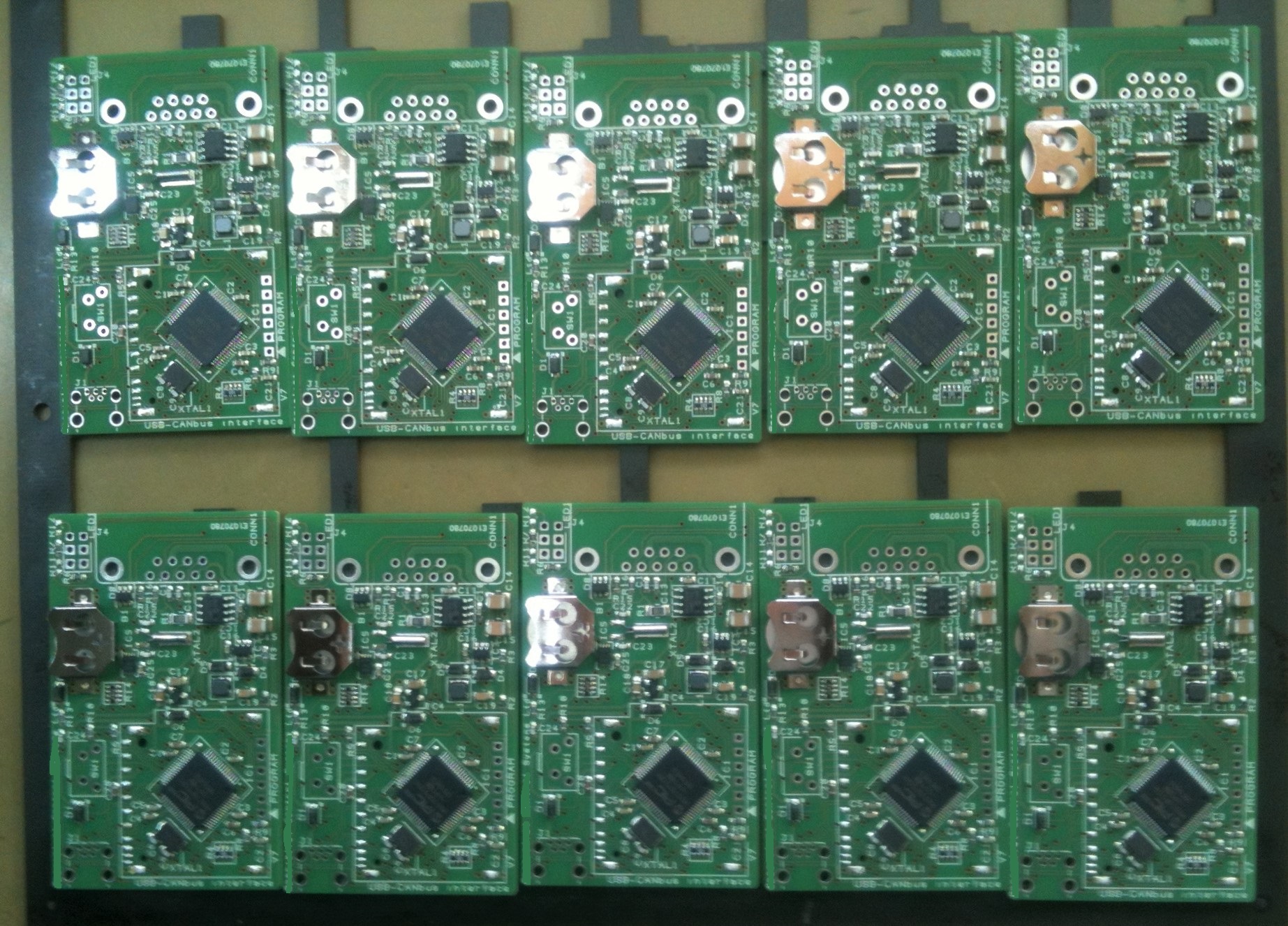

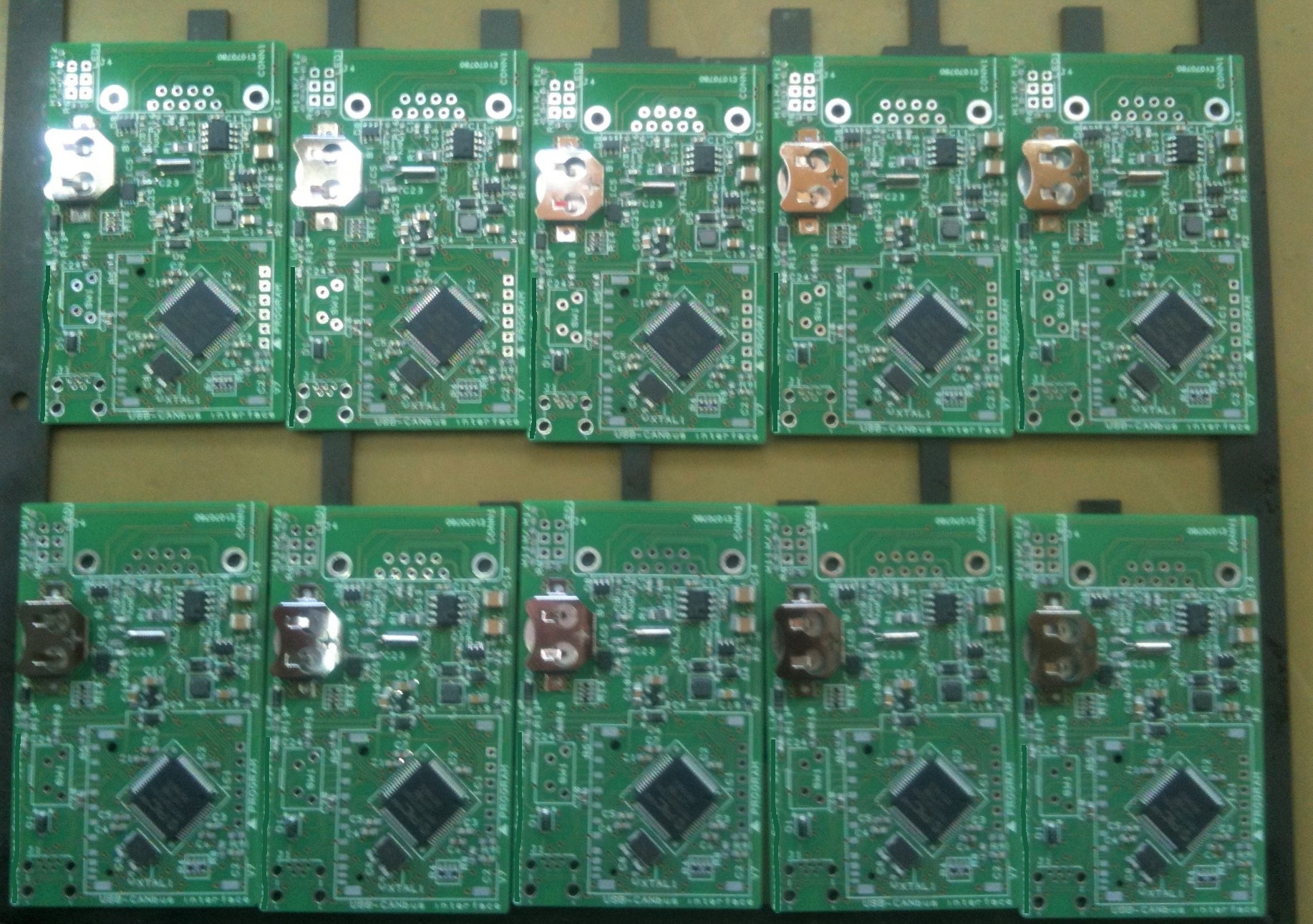

We offer an assembly service for customers who only have requirements for low volumes of products.

We can perform conventional assembly and surface mount assembly in low volume. All assembly work is performed by hand or by use of manual assistance machine.

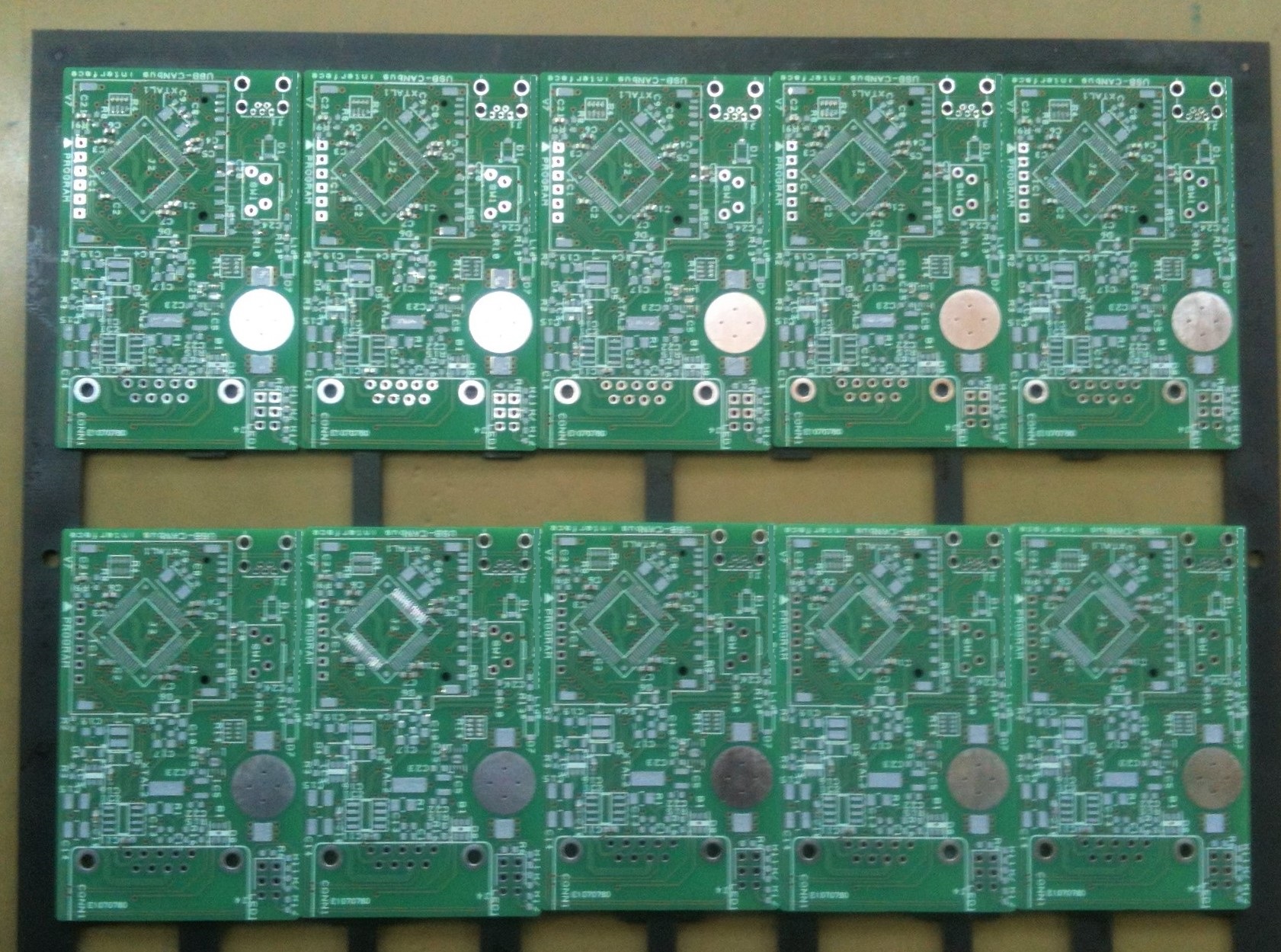

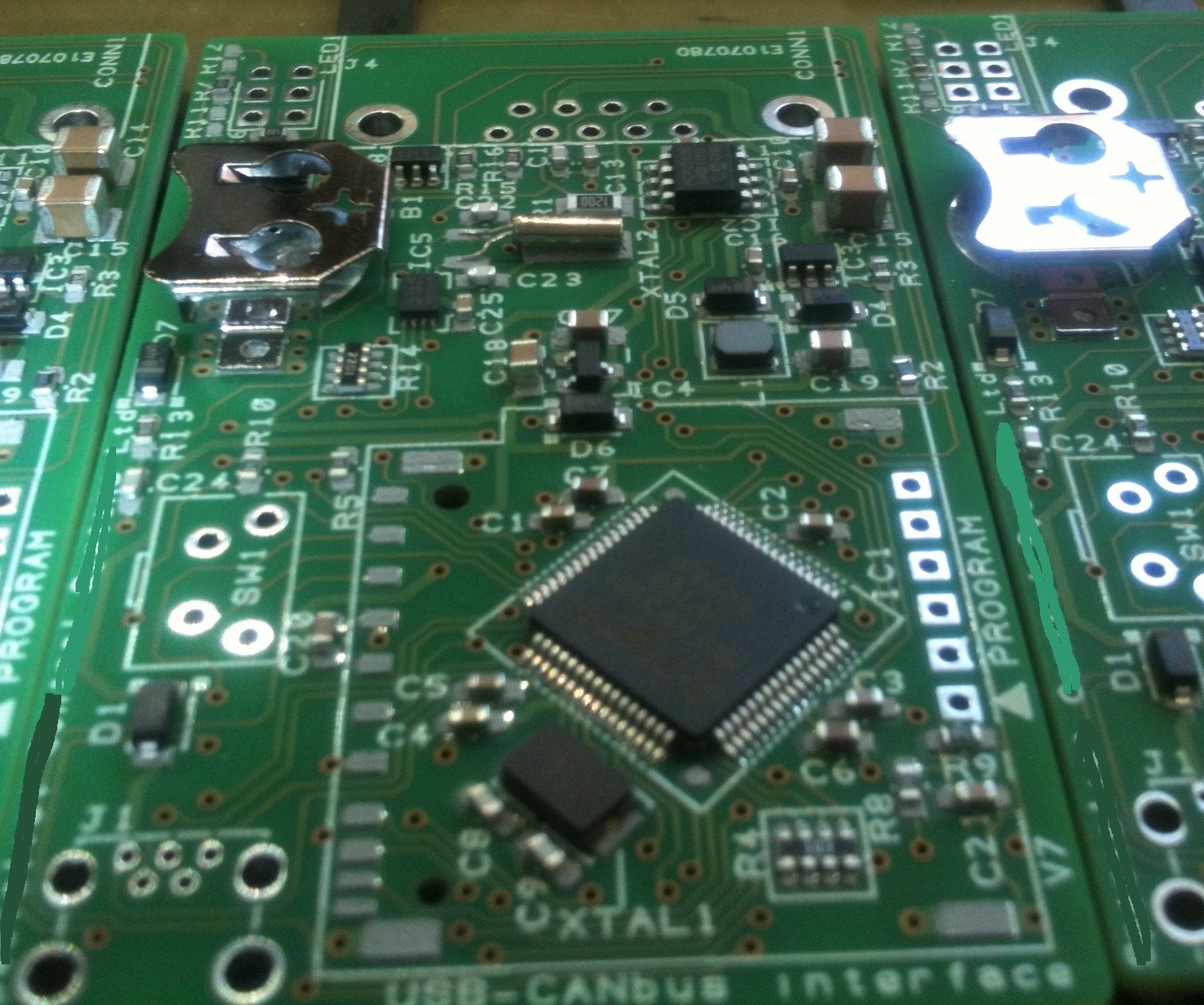

We generally impose a limit of no more than 500 surface mount components per board, this is due to the amount of time required to place the components on the board. The solder paste used in surface mount assembly has a time limit for its viability of around 2 hours. We paste the board, we place the components and then we reflow the boards in the oven, this all needs to take no more than 2 hours. If the solder paste loses its viability then the solder joints formed during reflow could be poor quality and your board could fail as a result.

If your design includes more than 500 surface mount components, please still request a quote, it doesn't cost you anything, and we will decide if we are able to assemble it and let you know.

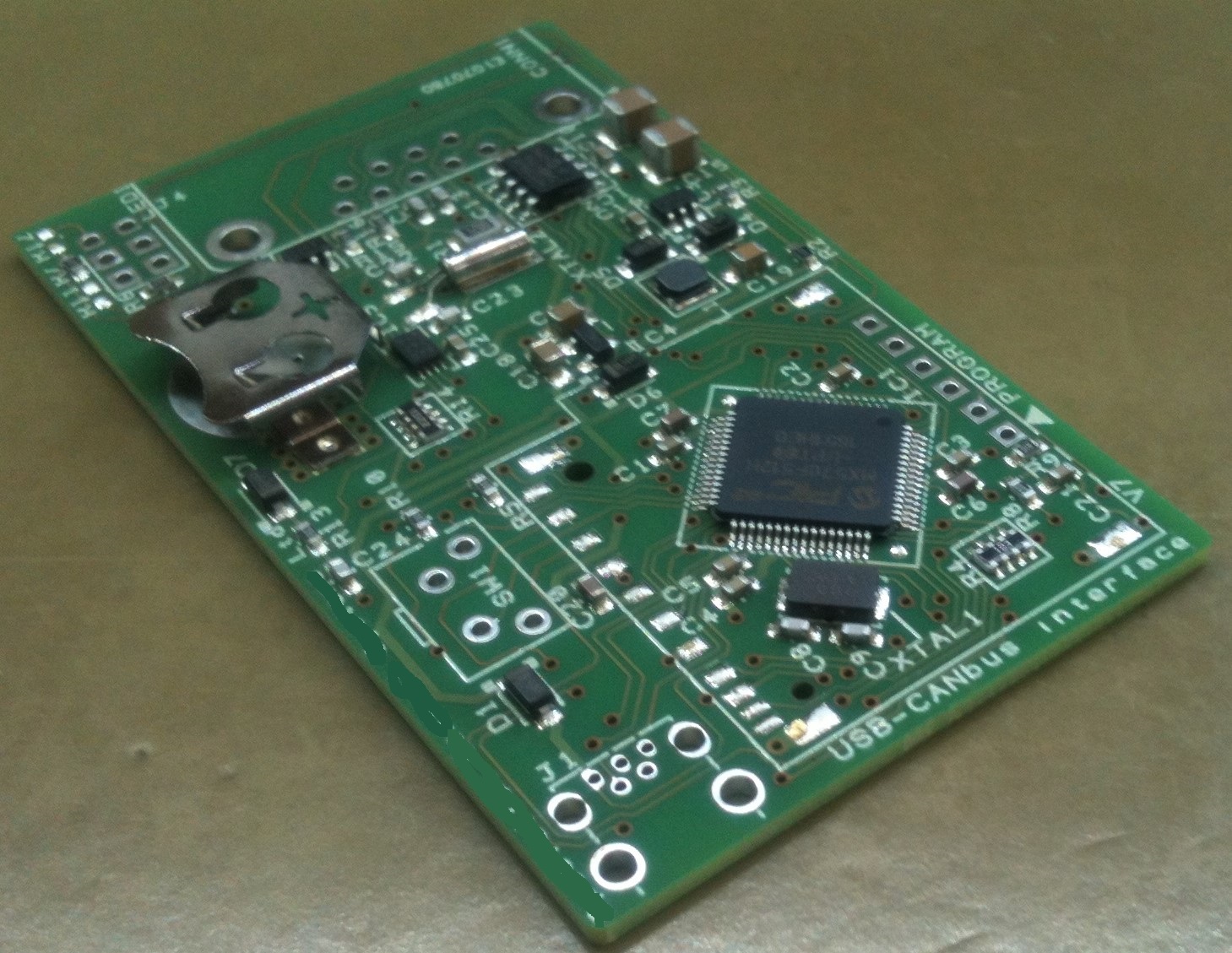

The maximum board size that we can accept is 230mm x 230mm, this limitation is due to the size of the reflow oven and limitations of hand assembly.

Currently we can assemble most types of surface mount components except BGA packages, the following is a list of limitations. If you are not sure please ask for a quote, it's free!

We can assemble SMT components on both sides of the board, however the cost increases because 2 stencils are required and also the components assembled on the first side need SMT adhesive to ensure they don't move or fall off during reflow of the other side.

We impose no limits on the number of components of this type and there are no limits on the board size.

We generally prefer to source our own components and we hold significant stock of many common components such as resistors and capacitors, also many common semiconductors. We are able to accept free-issue components providing the components are supplied in their original packaging and are in good condition. How the components are packaged will affect the cost, for instance if you want to free-issue components in RS components standard packaging then the assembly cost will be higher because we have to remove each component from its own individual pack and quite often from its own individual piece of tape.

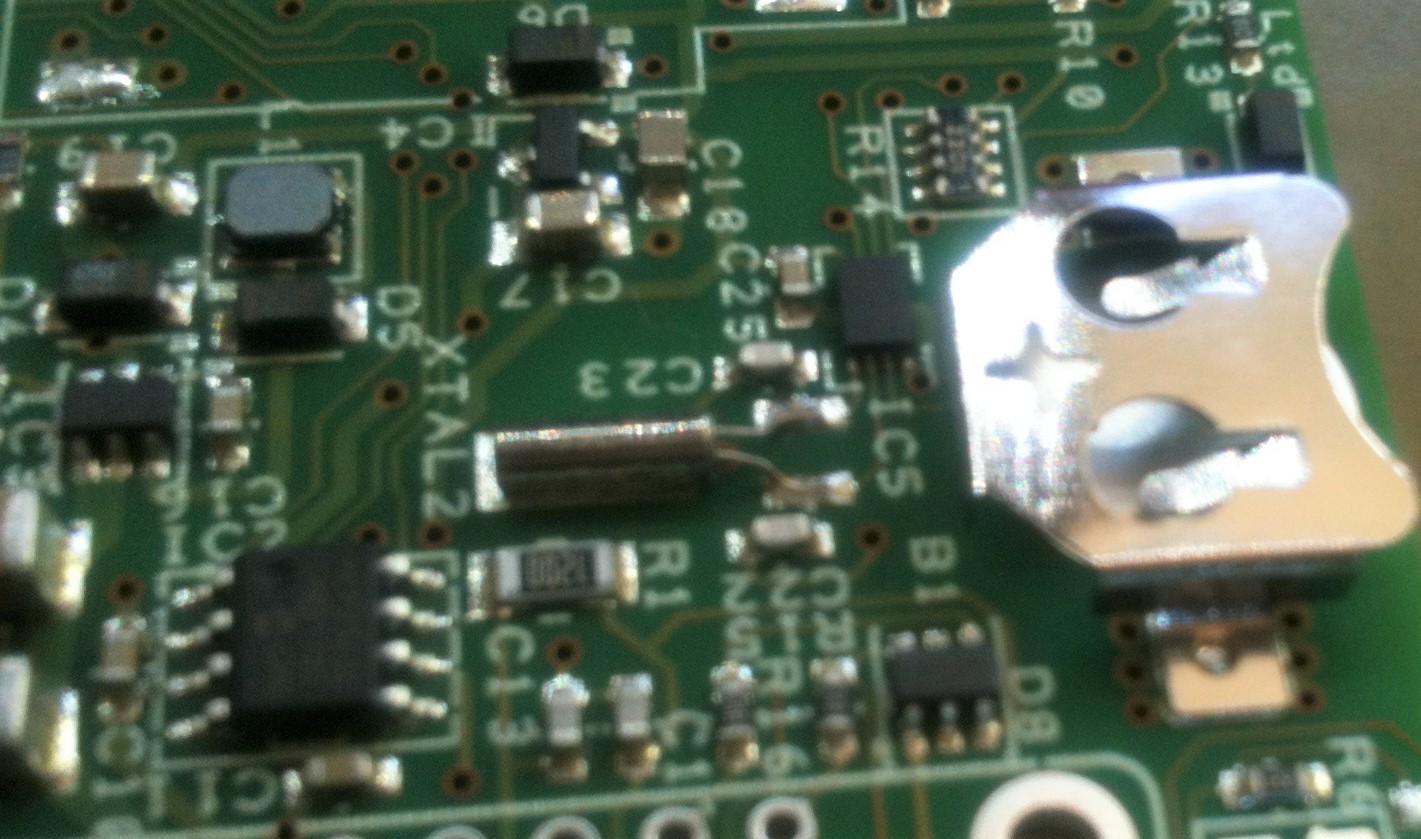

First we use a solder paste stencil to apply solder paste onto your PCB, the apertures in the stencil allow solder paste to be placed on each individual component pad. Then we place the components on the boards, if the boards are small enough we will place the components on several boards at once.

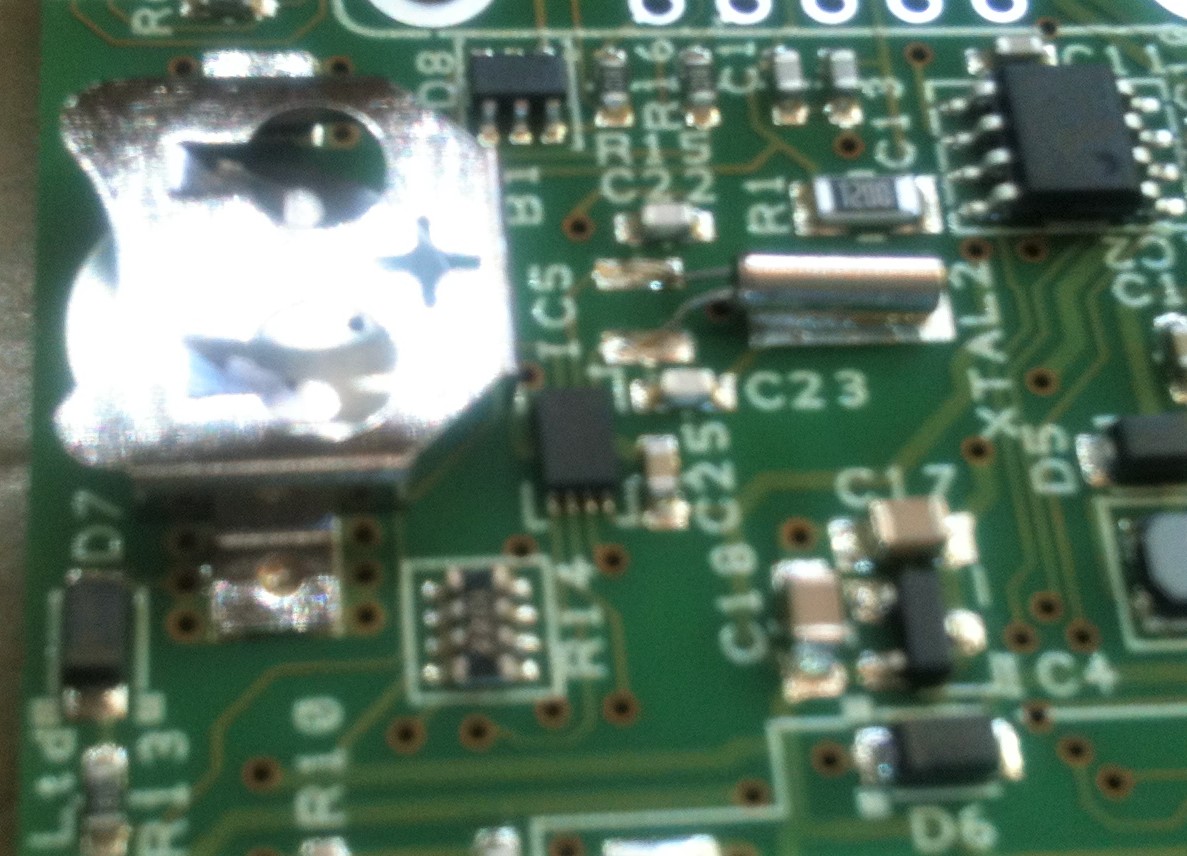

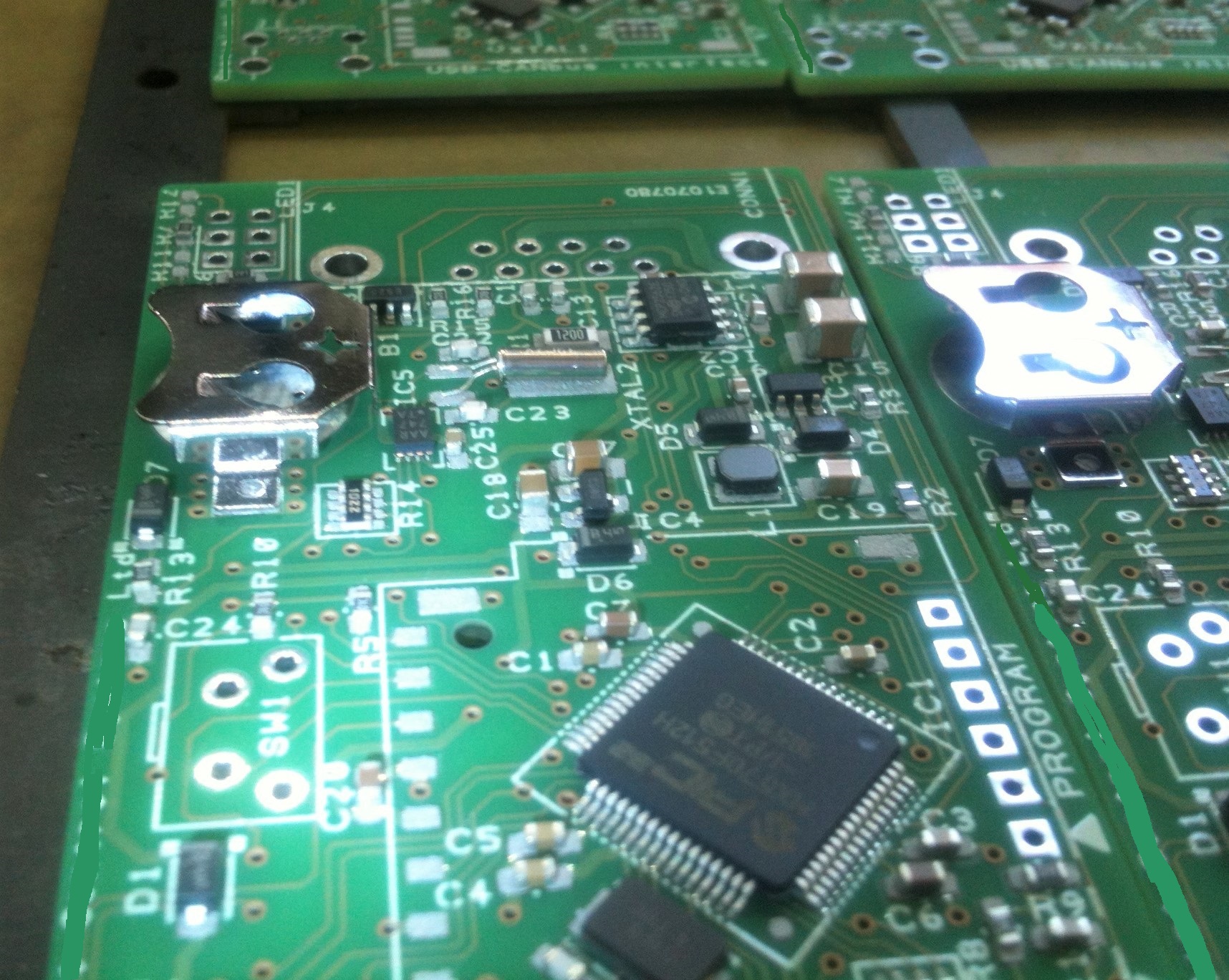

For surface mount assembly we use a hand held vacuum pump for larger components such as 0805 (and bigger) resistors and capacitors and SOIC ICs, low pin count TQFP etc...

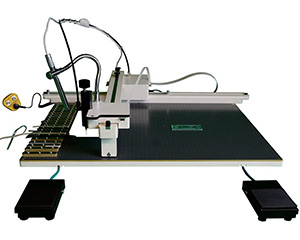

For surface mount assembly of smaller components or components that require more accuracy we use our camera assisted placement machine from Eurocircuits, placement is still being performed by hand but the machine permits high accuracy placement and also has a camera which enables the operator a better view and hence placement of components such as 0.4mm pitch TQFP and QFN is quick and easy.

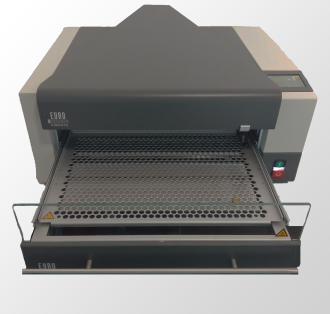

Once the surface mount components have been placed on the PCB we reflow the board using our EC-Reflow-Mate oven also from Eurocircuits, The reflow oven heats the board and causes all of the solder paste to melt at the same time which solders every joint all at the same time, this is much faster than soldering each joint separately.